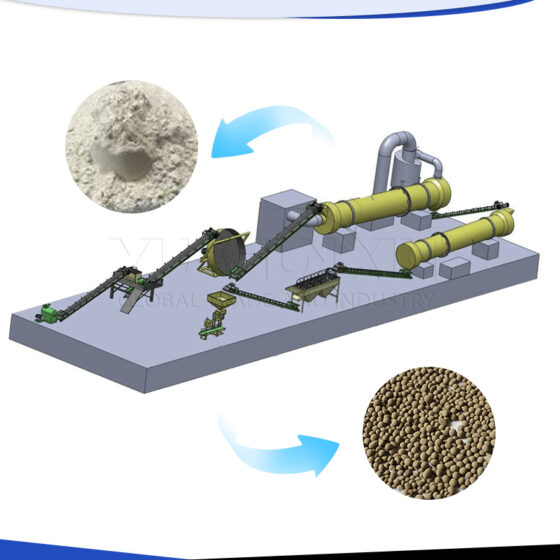

This fermentation equipment is mainly used to ferment organic waste such as pig manure, chicken manure, cow manure, sheep manure, Fungal residues, Residues of Traditional Chinese Medicine, crop straw and so on. It has the advantages of taking up little space, High corrosion resistance, Kill Pests and Eggs (can be set to a constant temperature of 60- 100°C) and many other advantages. It's a wise choice for breeding companies, Agriculture Recycling, and organic farming for the use of waste resources. In addition, Different capacities from 5-50m³ can be customized according to customers' needs.

Working Principle

First of all, The material to be fermented is fed into the fermentation cylinder from the feed port via the conveyor belt. While the materials are being fed, The main motor starts up and the motor speed reducer drives the main shaft to start the agitation. At the same time, Spiral blades of the stirring shaft rotate the raw materials, so that the materials are in full contact with the air, so aerobic fermentation is initiated.

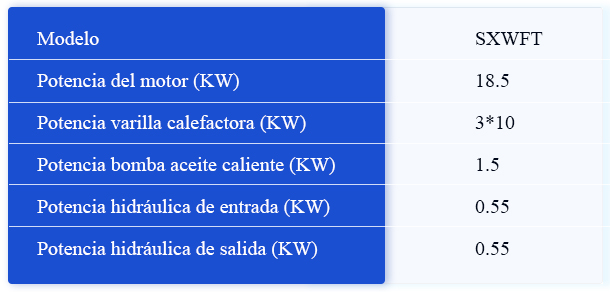

Secondly, The heating system of the electric heating rod at the bottom controlled by the electrical box begins to heat the heat transfer oil in the middle layer of the fermenter body. While warming up, The temperature of the cylinder body can be adjusted to a better fermentation temperature by the temperature sensor. Once fermentation is complete, Fermented raw materials are discharged through the discharge port for further processing.