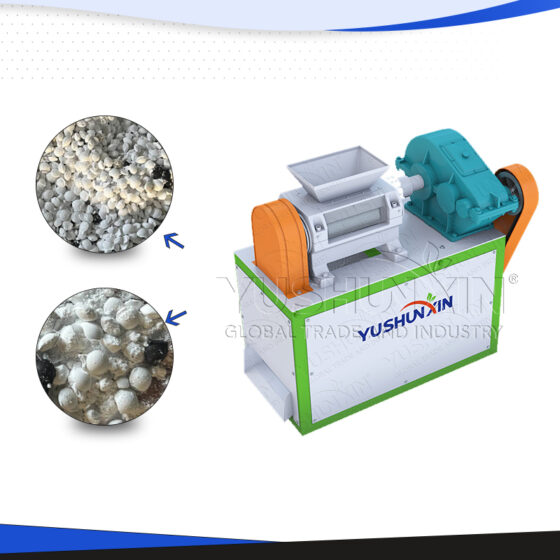

Double Roller Extrusion Granulator is the key compound fertilizer granulation equipment and has the characteristics of advanced technology, Reasonable design, Compact structure, novelty and utility and low power consumption; It is equipped with the corresponding equipment, which can form a small production line, thus forming the continuous production of a certain production capacity and production mechanization. The machine adopts the eugenic formula without drying and produces fertilizer by normal temperature; the product once laminated and formed, Meets the requirements of compound fertilizer technical specifications. Therefore, It is the improved machine for the production of high quality special compound fertilizer, Medium and Low Concentration and Renewable Energy Consumption of the Compound Fertilizer Industry.

Working Principle

This series of pelletizing rollers is extruded model, and its working principle is: Electromotor drives belt and pulley, Up Next, It is transmitted to the drive shaft by the speed reducer, and by synchronizing the open gear with the passive shaft, Achieving the work in the same direction. Material is added from the hopper, After Roll Extrusion Forming, Mold Release Granulation; and through a chain, The balls are transferred to the broken screen studio, sieving and isolating finished products (The balls), Up Next, remix with new materials and granular again.