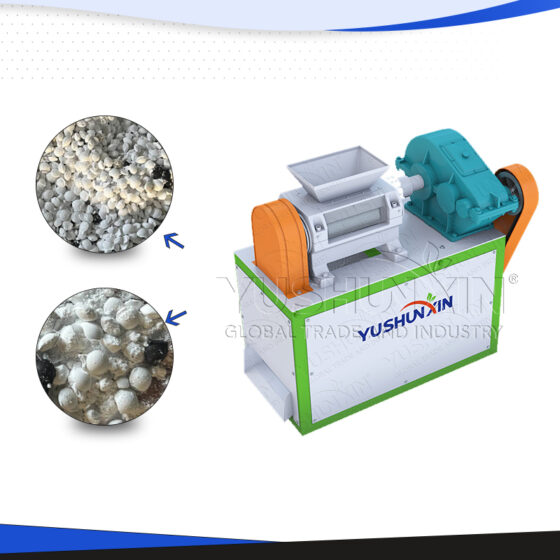

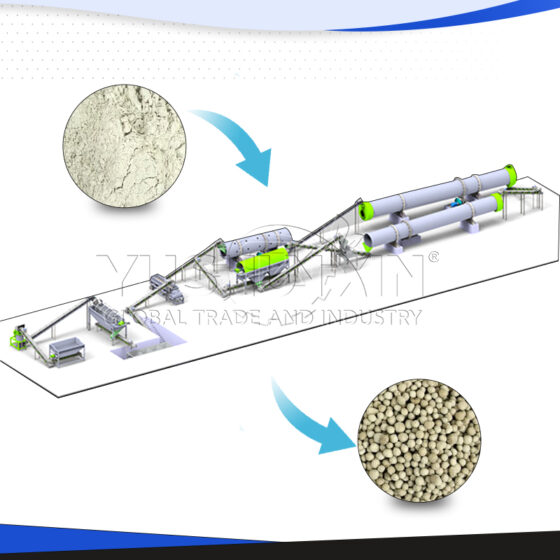

This machine is a new generation of rotary drum pellet mill developed by our company's staff according to the construction experience. The machine has the characteristics of beautiful appearance, Simple operation, Low power consumption, Long service life, Uniform drying and convenient maintenance, etc., which is the most advanced granulating equipment in China. The product is suitable for large-scale production of cold pellets, hot and high, medium and low concentration of compound fertilizer.

Working Principle

The electric motor drives the belt and pulley, It is then transmitted to the drive shaft by the speed reducer; Installing the open gear on the drive shaft, open gear is coupled with large gear ring that is fixed on the body, Achieving the work in the same direction. The material is added from the feed end and is located inside the tube. The function of the special structure inside the tube is granulation, Finally he leaves through the exit. Due to the continuous input of materials, Continuous rotation of the granulator can achieve mass production.