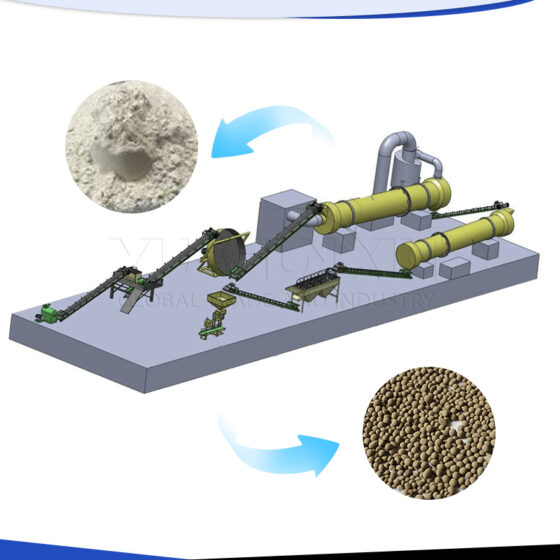

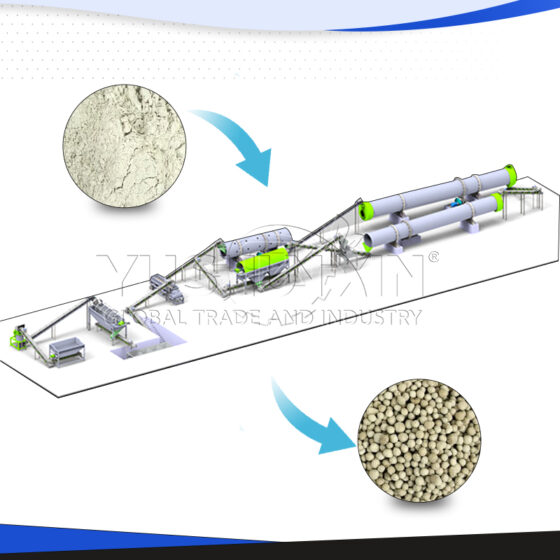

The Poultry Manure, Pigeon dung, Goose manure, Quail manure and other poultry manure is a superior type of organic fertilizer. Nitrogen content, phosphorus and potassium from chicken manure is 1,63%, 1,54% and 0,085%, respectively. Chicken manure should be thoroughly broken down using a decomposition agent before use, through which parasites and their eggs and infectious bacteria are inactivated and deodorized. The technological process of manure production is closely linked to the equipment of its production line. In general, The complete set of fertilizer production line equipment is composed of fermentation system, Drying System, Deodorization System, Dust Removal System, Crushing System, Mixing System, Granulation System, Screening System & Packaging System. The production flow of manure fertilizer is mainly as follows: Raw material selection → drying and sterilization → mixing and granulation → cooling and sieving → measuring and packaging → storage of the finished product.

Working Principle

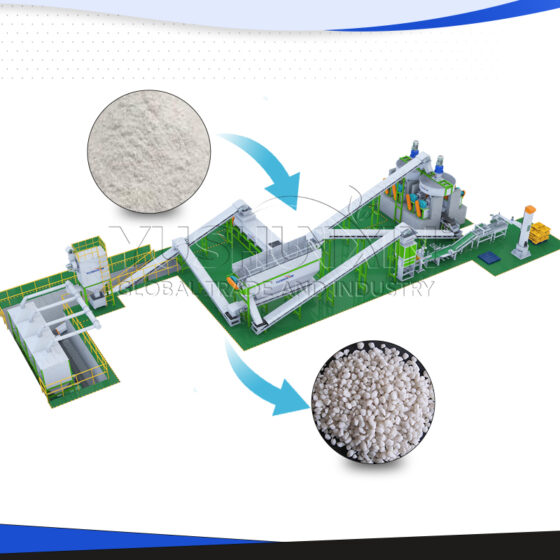

The Manure Production Flow (pigeon manure, goose manure, quail manure) It is mainly as follows: Raw Material Selection→Drying & Sterilization→Dosing & Mixing→Granulation→Cooling & Screening→Measuring & Packing→Finished Product Warehouse.

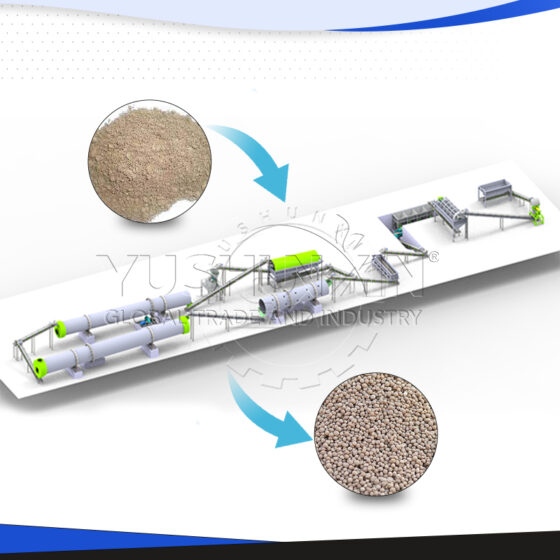

A more complex production flow of manure fertilizer (pigeon manure, goose manure, quail manure) It's as follows: First of all, Putting Organic Raw Materials (Animal manure, Household waste, Dead wood and rotting leaves, Biogas waste, Crop Residues) in the semi-wet material mixer after fermentation. Secondly, Add Nitrogen, phosphorus, Potassium and other elements (Pure Nitrogen, Phosphorus pentoxide, Potassium chloride, Ammonium chloride, etc.) to meet mineral element content requirements. One more time, Put them in the mixer to shake. Up Next, are fed into the granulator. Last, Go through the drying process, Sieving & Packaging. If the products do not meet the requirements, Feed them back into the granulator.