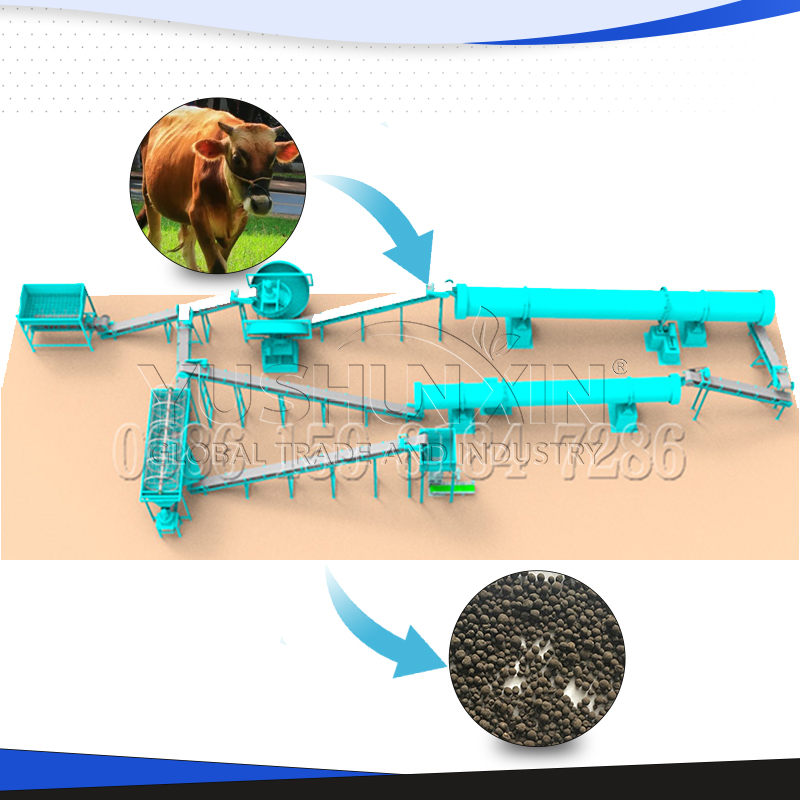

Cow manure from the septic tank can be pumped into the dewatering machine by a sludge pump with a defecation processor, and the water content of cow manure is around 40% After treatment; crops such as straw and rice bran (containing NPK) They can also be used as filler and then sprayed with biosclerosing agents. Mix 1KG of fungicide with 20KG of water to the raw material, then 1ton of raw material can be fermented. Flip once on 1-2 days, and usually 7-10 days materials can be fully mature.

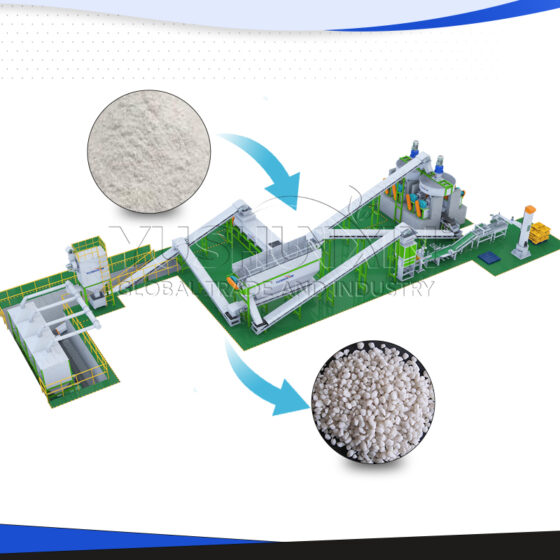

Complete equipment

Compost turner, Semi-Wet Material Shredder, Horizontal mixer, Pelletizer, dryer, Chiller, Rotary drum sieve, Coater, Packaging Equipment, conveyor belt, etc.

Main Steps to Produce Cow Manure Fertilizer

- Collection and dehydration:Collect fresh cow manure and dehydrate it using a cow manure dehydrator machine to remove excess moisture. This step helps to reduce the volume of manure and makes it easier to handle.

- Composting:Transfer dehydrated cow manure to compost bins or piles. Use a compost turning machine to turn and mix manure regularly to ensure proper aeration and decomposition. Monitor temperature and moisture content during composting. The composting process usually takes several weeks to complete.

- Crushing and mixing:Once the composting process is completed and the cow manure is decomposed, Shreds composted material into smaller particles using a shredding machine.

- Mixture:Mix shredded composted cow manure with other organic materials or additives such as crop residues, agricultural residues or microbial inoculants to improve nutrient content and microbial activity.

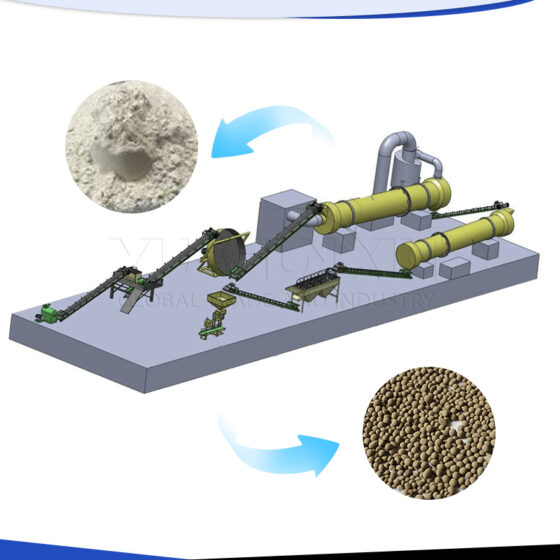

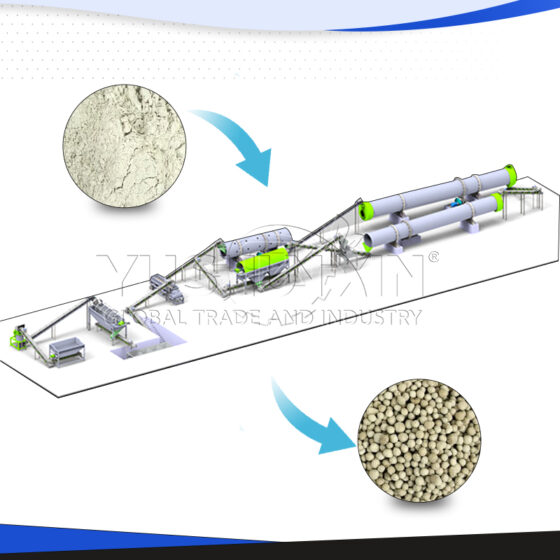

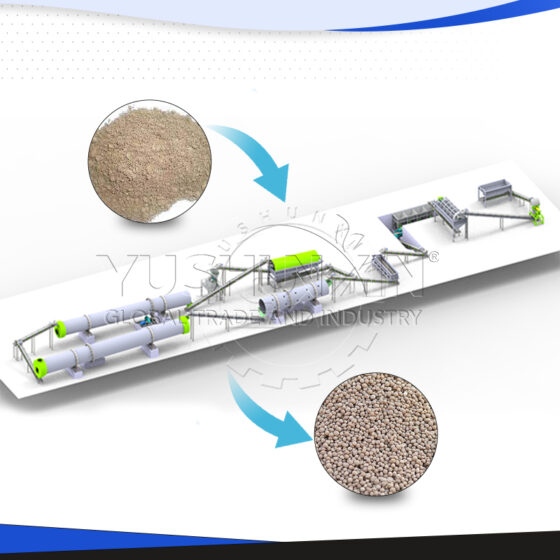

- Granulation:The mixed material is fed into a disc granulator to form granules. This step helps improve fertilizer handling and application.

- Drying:Drying Granulated Cow Manure Fertilizer Using a Drying Machine. This step reduces the moisture content of the fertilizer to improve its shelf life and prevent it from clumping.

- Cooling:After drying, Cool the compost pellets with a cooling machine. This step helps stabilize the pellets and prevents them from sticking to each other.

- Sieving:Pass the cooled compost pellets through a sieve to separate the larger or smaller particles and ensure a uniform particle size.

- Packaging:Last, Pack the sifted compost pellets into bags or containers using a packaging machine. Ensure proper labeling and storage to maintain fertilizer quality.

transformar el estiércol en abono orgánico

Buenos días,

Estoy interesado en una línea de producción de fertilizante orgánico de 2 T/H que termine en una línea de envasado con el producto granulado. Me interesa diferenciar en dos el proyecto, por un lado la línea de compostaje y por otra la de fertilizante desde trituración y mezcla. El producto base será purín, estiercol, gallinacea y otros estructurantes. Es importe que me manden detalles de implantación y precio.

Gracias