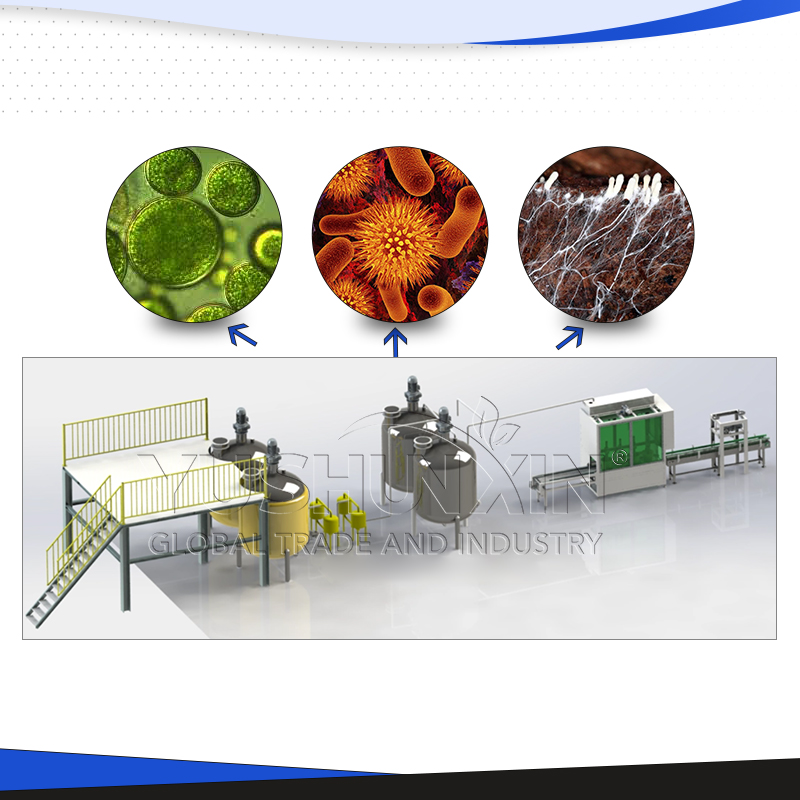

The bio liquid fertilizer production line adopts the liquid biogas chelation and complexation process, amino acid, humic acid, macronutrient, Secondary nutrient, micronutrient. And it has a whole strict operation process and systematic management methods. Fertilization operation can almost eliminate labor, which greatly saves labor costs. More and more soil and fertilizer experts, Experts in agricultural technology extension, Distributors of agricultural equipment and farmers have realized the importance of biological liquid fertilizers.

Compared to traditional superphosphate, granulated compound fertilizer and other types of fertilizers, Liquid bio fertilizer has obvious advantages. It is a fast-acting fertilizer with the advantages of good solubility in water and no residues. Its effective absorption rate is more than double that of ordinary fertilizers, that can reach 80%-90%. And the effect of fertilizer is fast, which can solve the nutritional needs of high-yielding crops during the rapid growth period.

Suitable raw materials

Biogas liquid, Livestock and poultry wastewater, Pharmaceutical Process Waste, amino acid residues, macronutrients, Secondary nutrients, Micronutrients, etc.