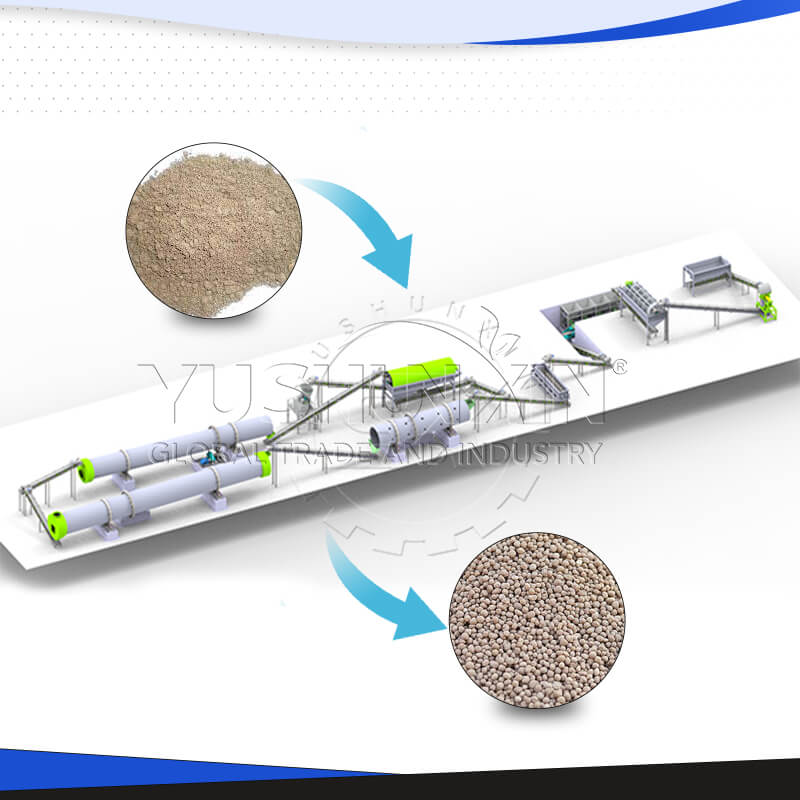

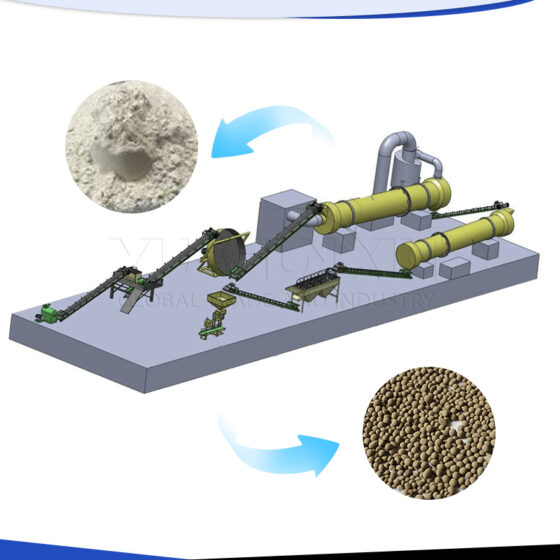

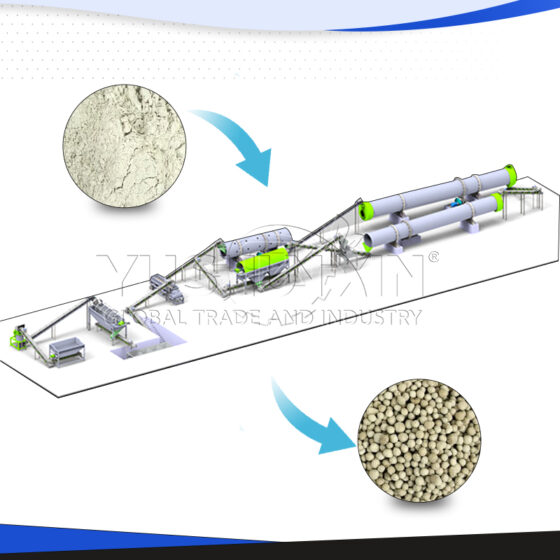

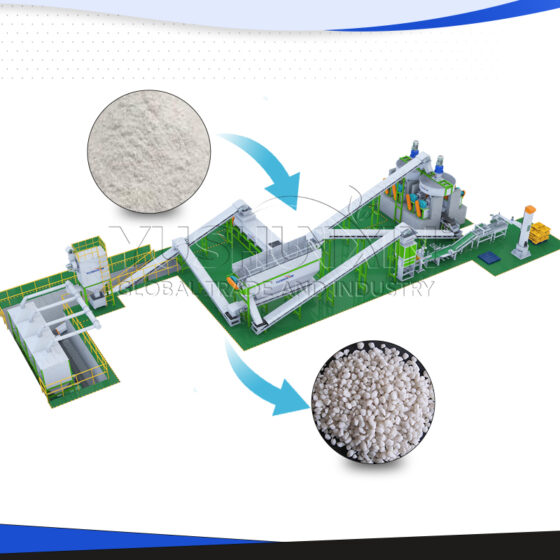

Phosphate fertilizers are typically derived from phosphate rock, a naturally occurring mineral containing high concentrations of phosphorus. And the phosphate fertilizer production line can turn phosphate rock into fertilizer, Mainly including grinding, acidification, Secondary aging and granulation.

Production Flow

- Milling:First of all, the prepared phosphate rock is ground into powder using the Raymond grinding system for better acidification.

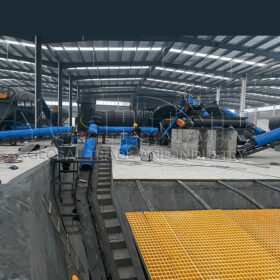

- Acidification:After grinding, The powder is sent to the stainless steel mixer by a screw conveyor, at the same time, Sulfuric acid or nitric acid from stainless steel storage tanks is also injected into the mixer. The agitated material will be acidified in the acidification tank.

- Secondary aging:After some time, The acidified material must be transported to the secondary aging area for ripening.

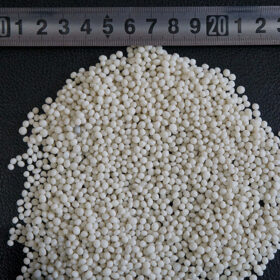

- Granulation: Aged material can be converted into granules by the rotary drum granulator.

- Drying:With the help of a rotary dryer, Granulated fertilizer dries to remove excess moisture.

- Cooling and screening:Dry fertilizer pellets are cooled and screened to remove dust or fines.

- Packaging and storage:The finished granulated phosphates are packaged and stored in a dry and cool place.

The phosphate fertilizer production line plays a crucial role in providing farmers and ranchers with the means to improve crop productivity, soil fertility and nutrient management. It has the character of a lower investment, Fast results and good economic benefits.