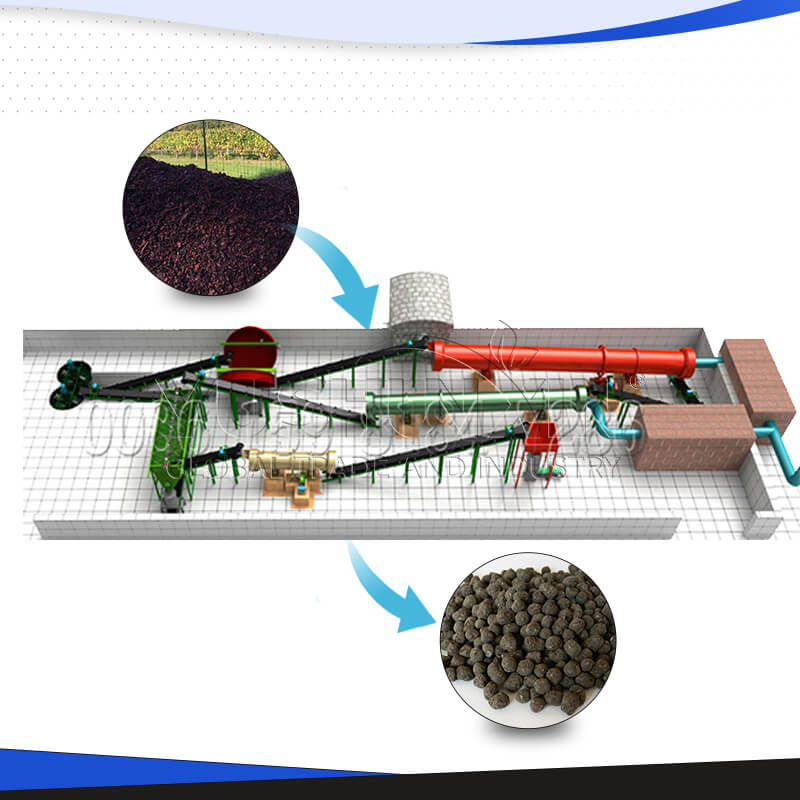

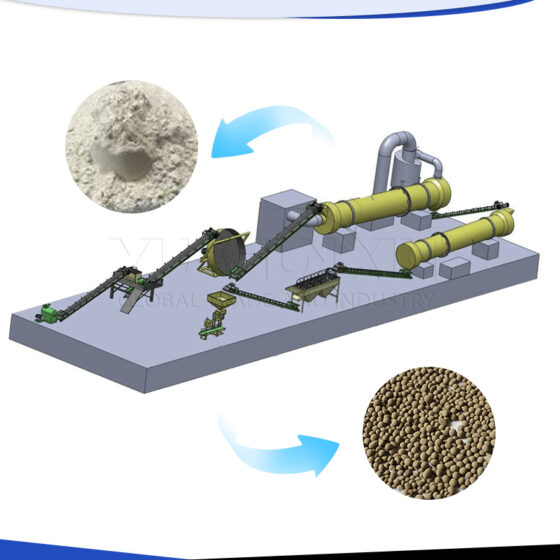

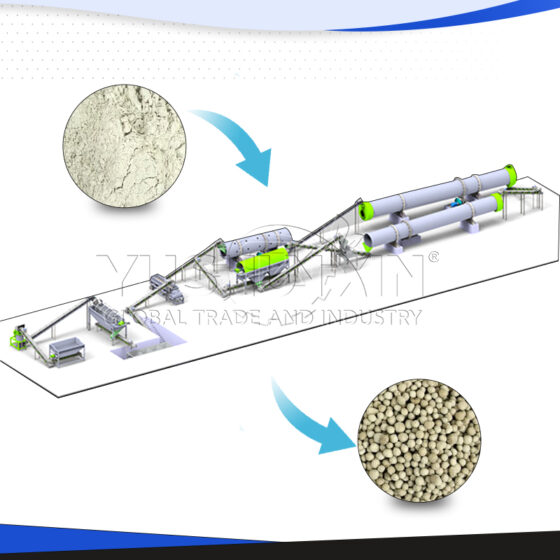

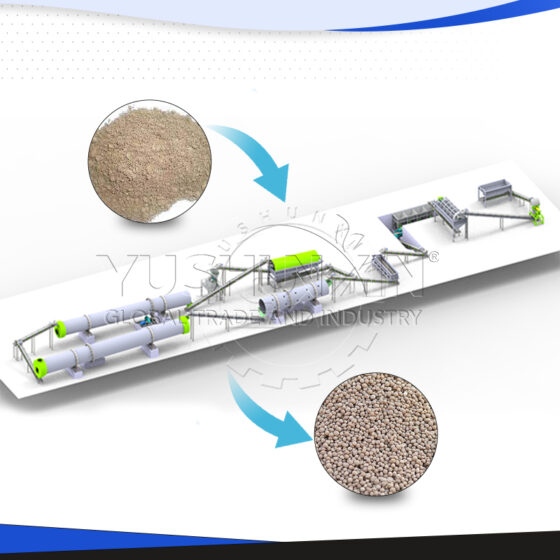

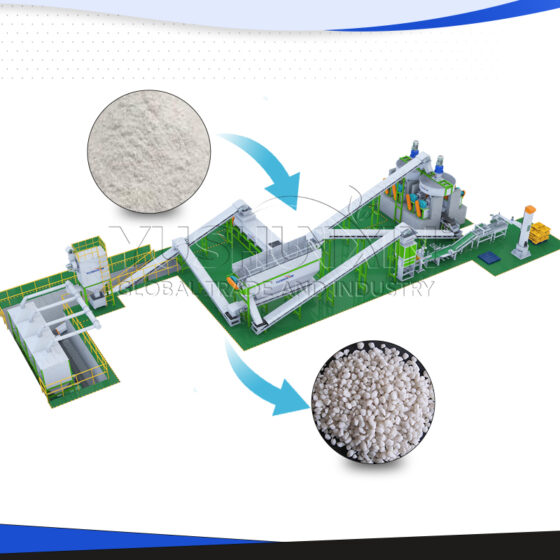

The organic waste fertilizer production line uses organic waste as raw material, such as organic waste, straw, human excrement, Livestock and poultry, cake flour, Agricultural and secondary products, then fermented, Deodorizes and decomposes completely to make fertilizer.

Operating Flow of Fertilizer Production Line Equipment from Organic Waste

- The raw material is accumulated and fermented.

The production of any type of qualified, high-quality organic fertilizer must go through composting and fermentation.

- Mixing and crushing

The crushing machine includes the semi-wet material crusher, Chain Shredder, Hammer Crusher, etc.; The mixing machine includes the horizontal double shaft mixer, Horizontal mixer, Single Shaft Mixer, etc.

- Granulation

In the production of organic fertilizers, The choice of granulation method is very important. Today, There are mainly different forms, such as the type of disc, Drum Type, The type of extrusion.

- Drying

Most materials have formed granules after granulation, But at this time the pellets still need to be dried because their water content and strength cannot reach the standard.

- Cooling

The dried granules are sent to the cooler via the conveyor belt to cool to near room temperature, so that the strength of the granules is improved and their water content is reduced.

- Sieving

In the cooled granules there are still some powdery materials, so it is necessary to sift fine powder and large particles, and then let them be processed by certain machines.

- The final products must be coated, Up Next, A protective film is formed on the surface of the particles to insulate them from outside air.

- Qualified products are packaged using an automatic packaging scale.