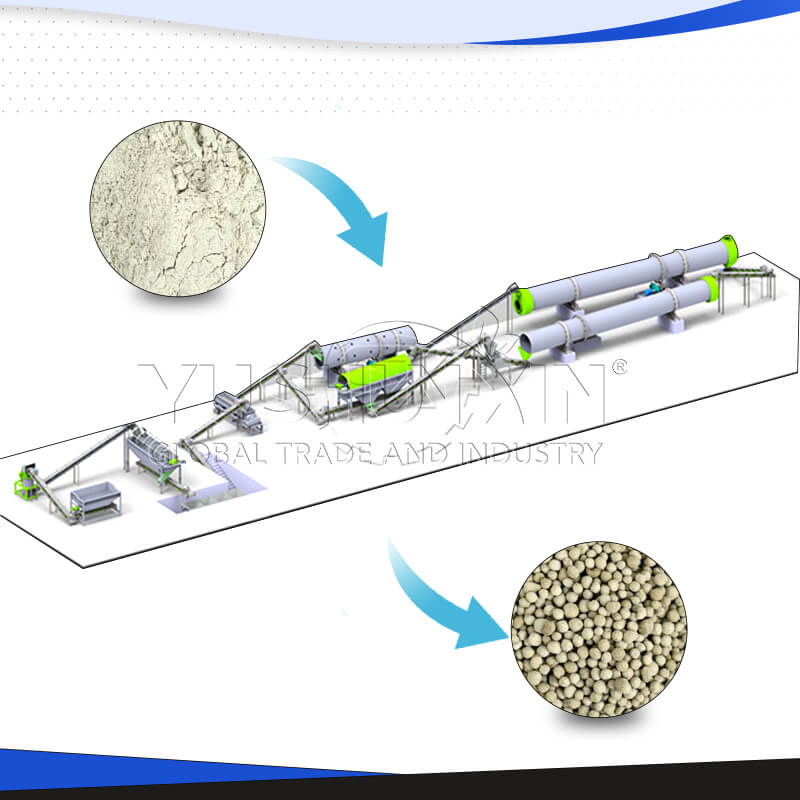

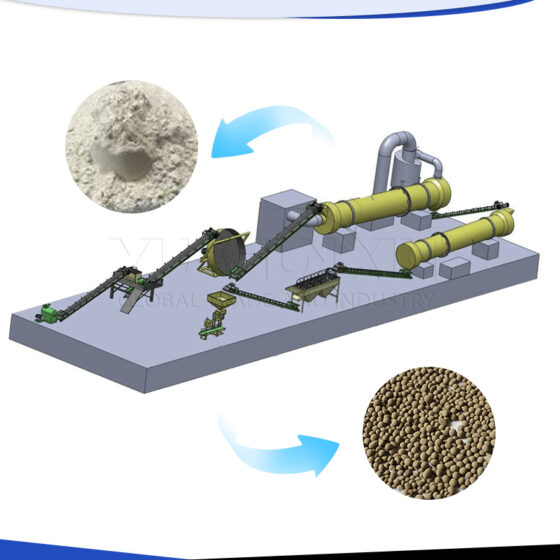

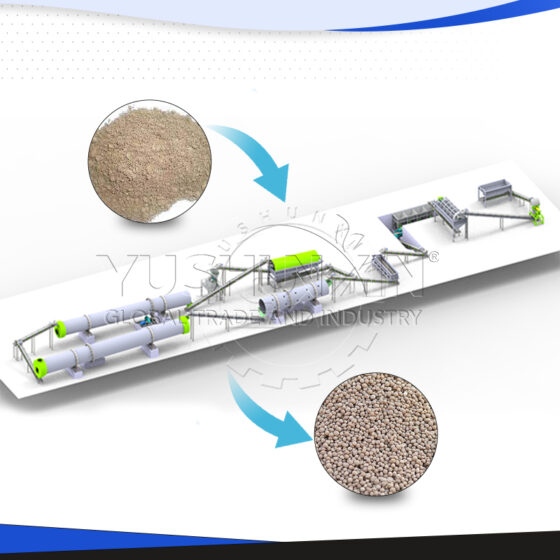

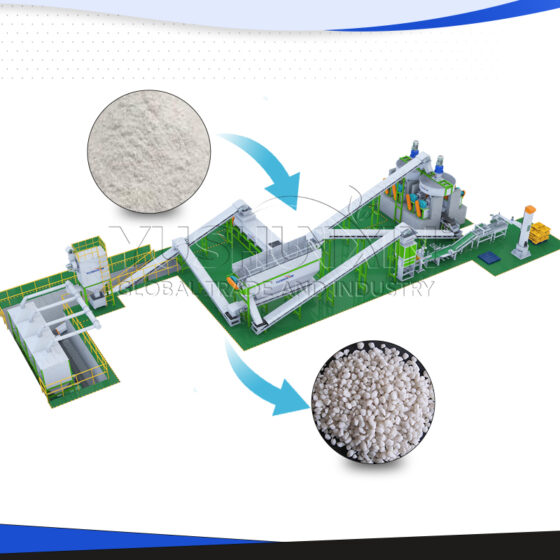

The limestone fertilizer production line is for making limestone pellets or calcium carbonate pellets. Typically consists of several stages, including grinding, sieving, mixed, granulation, Drying and cooling. Limestone fertilizer is commonly used to adjust the pH level of the soil and provide plants with a source of calcium.

Work Process

Milling: Limestones are ground into powders of 200 meshes by means of the Raymond mill.

Mixture: Limestone powder must be mixed with other components such as ammonium nitrate, phosphate and potash to create a complete fertilizer mix. The amount of each component used will depend on the specific formulation of the fertilizer.

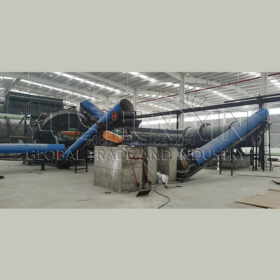

Granulation: Up Next, The compost mixture can be granularized to form small pellets that are easier to handle and apply. This can be done using a disc granulator or a binder bolt mixing granulator.

Drying: With the help of a rotary dryer, Granulated fertilizer dries to remove excess moisture.

Cooling and screening: Dry fertilizer pellets are cooled and screened to remove dust and fines.

Packaging and storage: Finished granular limestone fertilizer (Water Soluble) Packaged and stored in a dry and cool place.

The limestone fertilizer production line has the character of lowest investment, Fast results and good economic benefits. The whole process of the equipment is compact, scientific and advanced. Energy savings and reduced consumption, No waste disposal, Stable operation, Reliable operation, Convenient maintenance.