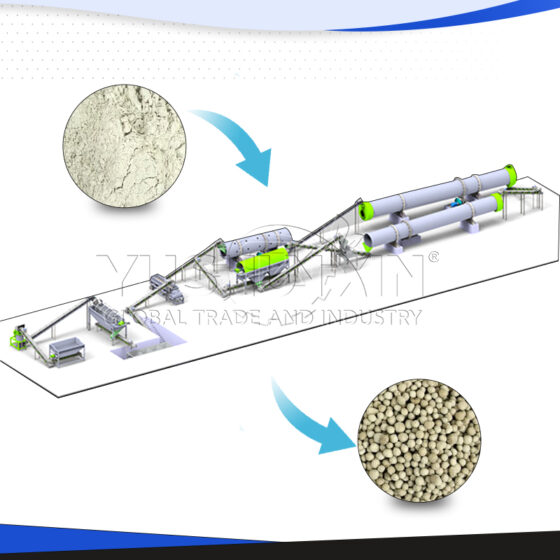

The water soluble fertilizer powder production line is a system of automated equipment designed to produce water soluble fertilizer powder, suitable for agriculture, Horticulture and other industries. Its main function is to process various solid raw materials through crushing and mixing procedures to create high-quality powdered water-soluble fertilizers.

Production Process

1.Preparation of Raw Materials

Select macronutrients that meet standards (as ammonium nitrate, phosphate, potassium sulfate), Micronutrients (Like Boron, zinc, iron, copper, manganese, molybdenum) and other auxiliary materials (as anti-caking agents, Solubilizers).

2.Pretreatment

For raw materials, especially those of mineral origin, Use a grinder to pulverize them to a certain particle size for better mixing and higher solubility.

Sieve the crushed materials using a vibrating screen to remove oversized particles and impurities, resulting in a fine, uniform powder.

3.Measurement

Accurately weigh each raw material according to the pre-designed fertilizer formula to ensure that the nutrient ratios of the final product are correct.

4.Mixture

Add the various raw materials into a mixer in the specified proportions. Use mechanical agitation to ensure complete and uniform mixing, ensuring consistent nutritional content in every batch of fertilizer.

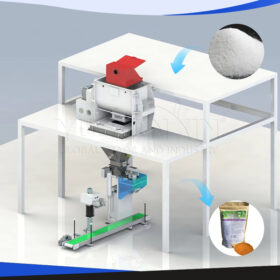

5.Quality Control & Packaging

Perform sample tests on the produced water-soluble powder fertilizer to confirm its solubility, Nutrient content, pH value and other standards.

Package the qualified product in specified weights using moisture-proof and light-resistant materials to ensure the stability of the fertilizer during storage and transportation.