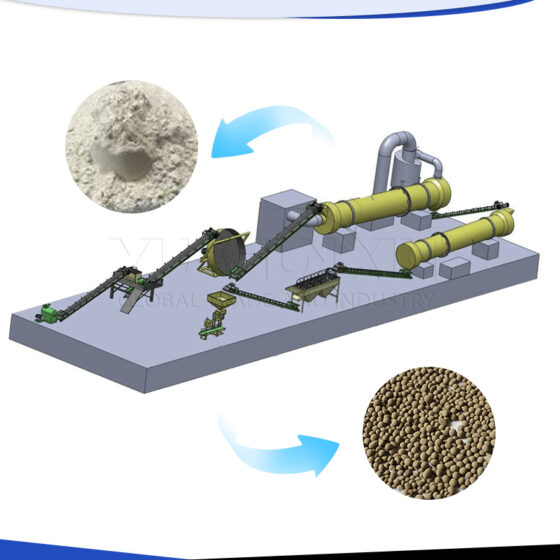

This machine can be used to separate water from livestock droppings, Manure, biogas waste and slurry, Kitchen waste, etc.

Animal excrement is collected in a collection pond, in which there is a mixing machine that can mix all the excrement continuously. Up Next, The mixed excreta is transported to the solid-liquid separator by a plunger pump. After processing, Solids fall onto the pile of solid material under the solid-liquid separator machine, and the liquid drains into the desiltrotor. After decanting and composting, The liquid obtained can be diluted as irrigation water. The solid matter obtained contains little water, making it easy to carry. It can be used to produce biofertilizer or sold as a fertilizer material.

Viability:

This type of machine is high efficiency. After being processed in the solid-liquid separating machine, The moisture content of the solid residue is between 30-45% . The output quantity and moisture content can be adjusted. This machine is applied to different raw materials that need to be separated. The solid matter is convenient to be transported and is a good raw material for making fish fodder and bio-fertilizer.

Maintenance:

In general, The screen of this machine must be cleaned every shift. When cleaning, you should take down the shell roof cover, and you can use water torch to clean.