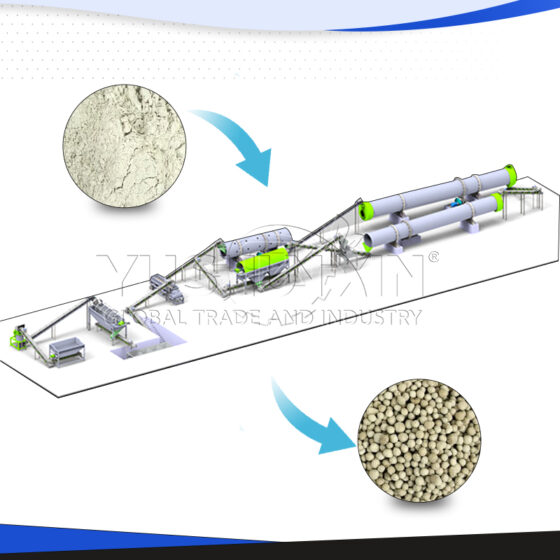

Rotary drum sieve is a new type of special self-cleaning material sieving equipment. It is widely used in screening various solid materials smaller than 300mm in size. It has high efficiency, Low noise, Low amount of dust, Long service life, Less maintenance, Easy maintenance and many other features. The screening capacity is 60 t / H~1000 t / h.

Working Principle

Through the reasonable rotation of the central separation cylinder of the equipment which is achieved by the transmission deceleration system, Self-Cleaning Rotary Drum Sieve Machine Starts To Work. The central separation cylinder is a sieve composed of a plurality of flat rings of steel in the shape of a ring, Tilting installed above the ground plane. At work, material enters the cylinder from the top, The cylinder then rotates to sift the materials. In the process of separation, the fine materials separated from top to bottom by the interval of flat circular steel mesh, and the coarse materials of the separating device are discharged into the crusher.