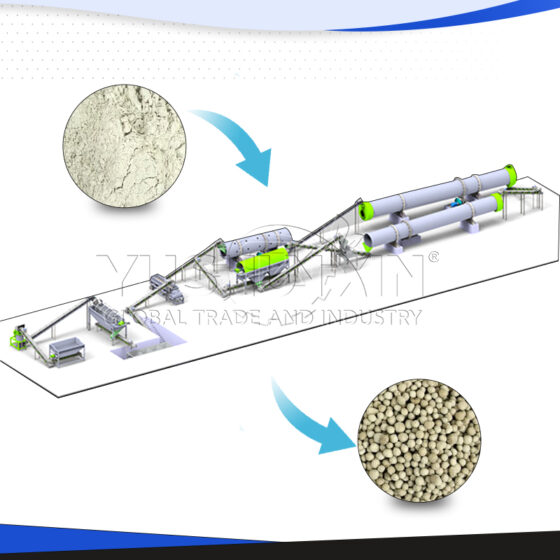

The semi-wet compost crusher is used to crush the organic fermentation biological fertilizer, Fertiliser for fermentation of urban household waste, Sludge Grass Charcoal, Rural garbage, industrial organic waste from straw, breeding livestock and poultry manure, etc.

Working Principle

Semi-wet fertilizer crusher is a professional crushing equipment for crushing material with high moisture and multi-fiber. The semi-wet material crushing machine uses high-speed rotary knife, The fiber particle size after crushing is good, which makes it have high efficiency and strong energy. The semi-wet material crusher is mostly used in the production and processing of organic fertilizer, and has good effect on raw materials such as chicken manure and humic acid.

The machine uses the two-stage pulverized rotor, and the material is first crushed into small particles and then crushed into fine powder, finally downloads.

This machine does not have the wallpaper, so more than 100 kinds of materials can be crushed and the machine will never be blocked. Even materials that have just come out of the water can also be crushed and will not be blocked by wet materials, preventing the engine from burning out and affecting production.